Slewing bearings are a crucial component in modern construction, mining, and industrial machinery. Designed to handle heavy loads and facilitate rotational movement, these bearings play a vital role in equipment performance and reliability. At Fanbuzhe, we provide high-quality slewing bearings engineered to meet the demands of cranes, excavators, wind turbines, and other heavy-duty applications. This guide will explain what slewing bearings are, how they work, their main components, and why choosing the right bearing matters for your machinery.

A slewing bearing, also known as a turntable bearing or rotary bearing, is a large-diameter bearing that accommodates axial, radial, and moment loads simultaneously. Unlike standard bearings, slewing bearings are designed for slow rotation under heavy loads. They are widely used in cranes, excavators, wind turbines, and other machinery that requires smooth rotational movement, with many of these critical components being sourced as reliable China slewing bearing.

The working principle of a slewing bearing is relatively straightforward yet mechanically sophisticated. Slewing bearings support the weight of the upper structure while enabling rotation around a fixed axis. This rotation is facilitated through rolling elements, such as balls or rollers, housed between inner and outer rings.

Load Handling: Slewing bearings manage axial loads (vertical forces), radial loads (perpendicular to rotation), and moment loads (torque from tilting or uneven weight distribution).

Rotation: As machinery operates, the bearing allows smooth rotation, ensuring stability and precise control.

Lubrication and Maintenance: Proper lubrication reduces friction and wear, extending the service life of the bearing and maintaining efficient rotational performance.

By understanding how slewing bearings function, operators can ensure safe and reliable performance, minimizing downtime and maintenance costs.

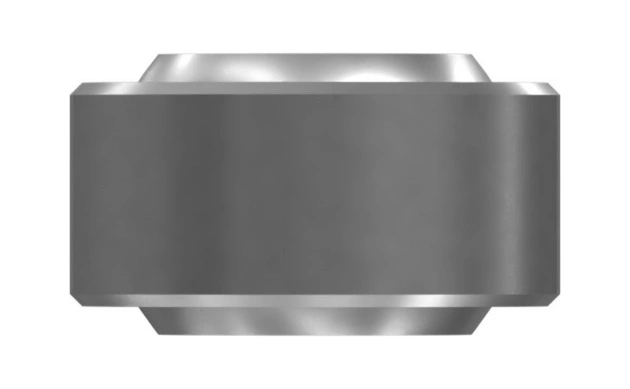

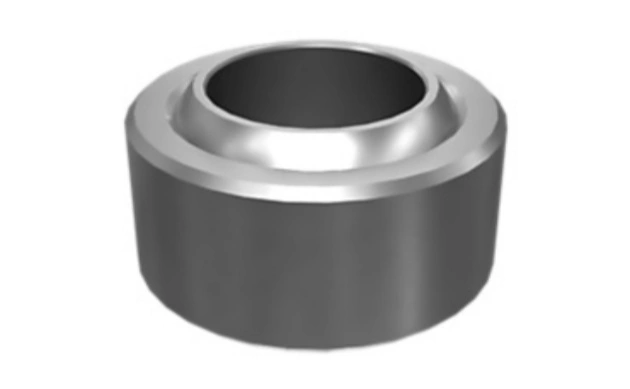

Slewing bearings consist of several critical parts, each designed to optimize load distribution and rotational movement:

Inner Ring: Provides a mounting surface for the rotating component and distributes radial and axial loads.

Outer Ring: Secures the bearing to the stationary structure and handles torque forces.

Rolling Elements: These can be balls or rollers that reduce friction and enable smooth rotation between the rings.

Raceways: Precision-machined tracks where the rolling elements travel to maintain stability and uniform load distribution.

Seals and Lubrication Systems: Prevent contamination and ensure the bearing operates under optimal conditions.

Understanding the structure of a slewing bearing helps in maintenance, troubleshooting, and selecting the right bearing for your machinery.

Selecting the correct slewing bearing is essential for maximizing performance, safety, and longevity. Poorly chosen or low-quality bearings can lead to premature wear, uneven rotation, and costly repairs. Key factors to consider when choosing a bearing include:

Load Capacity: Ensure the bearing can handle axial, radial, and moment loads of your application.

Size and Mounting: Bearings must fit precisely to prevent misalignment and stress concentrations.

Material Quality: High-grade steel and heat treatment increase durability and resistance to wear.

Manufacturer Support: Trusted suppliers like Fanbuzhe provide technical guidance, OEM compatibility, and reliable customer service.

By investing in high-quality slewing bearings, machinery operators reduce downtime, improve efficiency, and extend equipment lifespan.

Slewing bearings are a vital component in heavy machinery, enabling smooth rotation and supporting heavy loads. Understanding what slewing bearings are, how they work, their essential components, and selecting the right bearing can dramatically improve machine performance and reliability. At Fanbuzhe, we offer a comprehensive range of slewing bearings designed for durability, precision, and long-term efficiency. Explore our products today to ensure your equipment operates at its best and achieves maximum lifespan.