An Asphalt Paver, also known as a paver finisher or road paver, is a construction machine used to lay asphalt on roads, bridges, parking lots, and other surfaces. It evenly spreads and partially compacts hot mix asphalt (HMA), providing the foundation for a smooth, durable roadway.

The paver receives asphalt material from a dump truck through a hopper, then distributes it onto the roadbed via an internal conveyor system. At the rear, a screed levels and pre-compacts the material to the desired width and thickness, preparing it for final compaction by a road roller.

1. Uniform Asphalt Distribution

Ensures consistent pavement quality with minimal manual intervention.

2. Adjustable Paving Width & Thickness

Adaptable to various road construction requirements.

3. Advanced Control Systems

Modern pavers include automatic leveling and grade control for precision and efficiency.

4. Types of Pavers

The asphalt crawler pavers are typically categorized into wheeled and crawler (tracked) models. Crawler pavers offer better traction and stability on uneven or soft terrain, while wheeled pavers are faster and more maneuverable on firm surfaces.

Asphalt pavers are essential in the construction and maintenance of:

Highways and expressways

Urban and rural roads

Airport runways and taxiways

Industrial yards and parking areas

An asphalt crawler pavers is a critical machine for road construction contractors, offering high productivity, precise results, and a smooth surface finish that meets modern infrastructure standards.

An Asphalt Paver is a key machine in road construction, designed to lay hot mix asphalt (HMA) evenly over a prepared base. Its operation involves a coordinated process of material feeding, distribution, leveling, and pre-compaction.

Step-by-Step Working Process:

1. Feeding

Hot asphalt mix is delivered from a dump truck into the paver’s hopper. The mix then flows toward the conveyor system under gravity and vibration.

2. Conveying

Twin augers or conveyor belts transfer the asphalt mix from the hopper to the rear of the machine, where it is evenly spread across the paving width.

3. Leveling and Shaping

At the back of the paver, the screed plays a critical role. It levels the asphalt to the desired thickness and shape, using heating elements and vibratory systems to improve surface texture and uniformity.

4. Pre-Compaction

The screed applies initial compaction through vibration and tamping mechanisms, ensuring a stable and consistent mat before final rolling.

5. Automatic Controls

Modern pavers use electronic grade and slope sensors to maintain accurate thickness and surface level throughout the paving process.

6. Final Step: Compaction

After the paver lays and levels the asphalt, compactors or rollers follow to apply final compaction, achieving the required density and smoothness.

An Asphalt Paver is a complex yet well-integrated machine designed for efficient asphalt laying, commonly produced by a leading road machinery factory to meet industry standards. Its performance relies on several key components working in coordination:

1. Hopper

Located at the front, the hopper receives hot mix asphalt (HMA) from dump trucks. It temporarily stores the material and feeds it into the conveyor system.

2. Conveyor System

Beneath the hopper, conveyors (usually dual) transfer asphalt from the hopper to the rear of the paver. This system ensures a steady material flow for consistent paving.

3. Auger

Positioned just in front of the screed, the augers spread the asphalt mix evenly across the paving width before it reaches the screed.

4. Screed

The screed is the heart of the paver. It levels, spreads, and partially compacts the asphalt. Modern screeds include vibration and heating systems to enhance mat quality and smoothness.

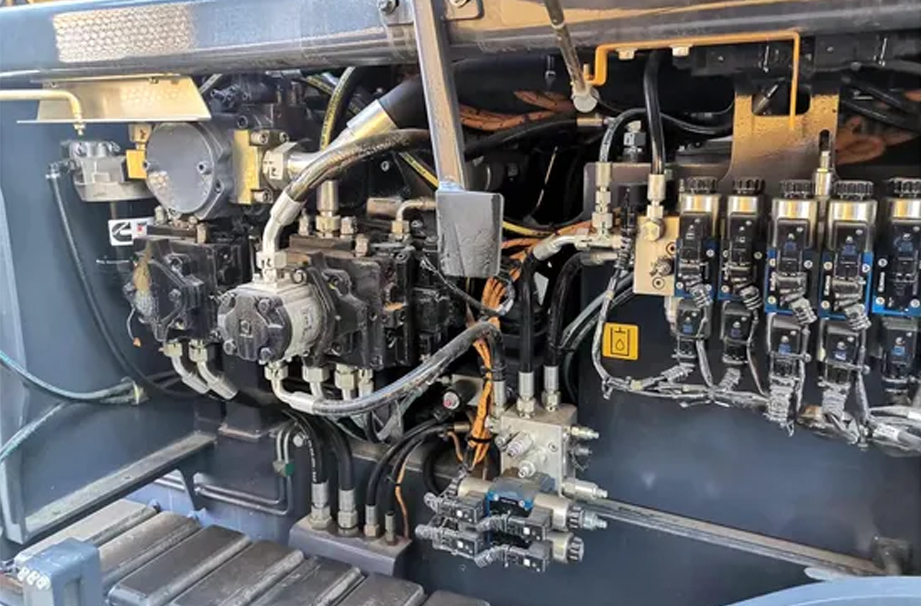

5. Engine & Hydraulic System

Powers the entire machine, including movement, material flow, and screed operation. High-performance engines and hydraulics ensure reliable and efficient paving.

6. Operator Platform & Controls

Provides the operator with full control over speed, paving width, material flow, and leveling. Many models feature digital displays and automation systems.

7. Track or Wheel System

Pavers come with either crawler tracks for better traction and stability or wheels for higher mobility and speed.

Regular maintenance of asphalt pavers is essential to ensure optimal performance, extend service life, and reduce downtime. Below are key maintenance practices:

1. Daily Cleaning

Clean the paver after each use to remove asphalt buildup.

Pay special attention to the screed, augers, and hopper areas.

2. Lubrication

Grease all moving parts and pivot points regularly as per the manufacturer’s schedule.

Use high-quality lubricants to reduce wear and prevent corrosion.

3. Engine & Hydraulic Checks

Inspect engine oil, coolant, and hydraulic fluid levels daily.

Replace filters and fluids at recommended intervals.

4. Screed Maintenance

Keep the screed clean and check for wear on plates and heating elements.

Adjust leveling sensors and vibration settings as needed.

5. Conveyor & Auger Inspection

Check conveyor belts and augers for wear, damage, or misalignment.

Ensure smooth and even material flow.

6. Electrical System

Inspect lights, controls, sensors, and wiring for proper function.

Replace damaged or worn-out electrical components promptly.

7. Track/Wheel System

Monitor track tension or tire pressure and adjust accordingly.

Look for cracks, cuts, or unusual wear patterns.

8. Regular Inspection & Preventive Maintenance

Follow a scheduled maintenance plan based on operating hours.

Keep records of service and part replacements.